TOP RATED

Industrial and Manufacturing Contractor

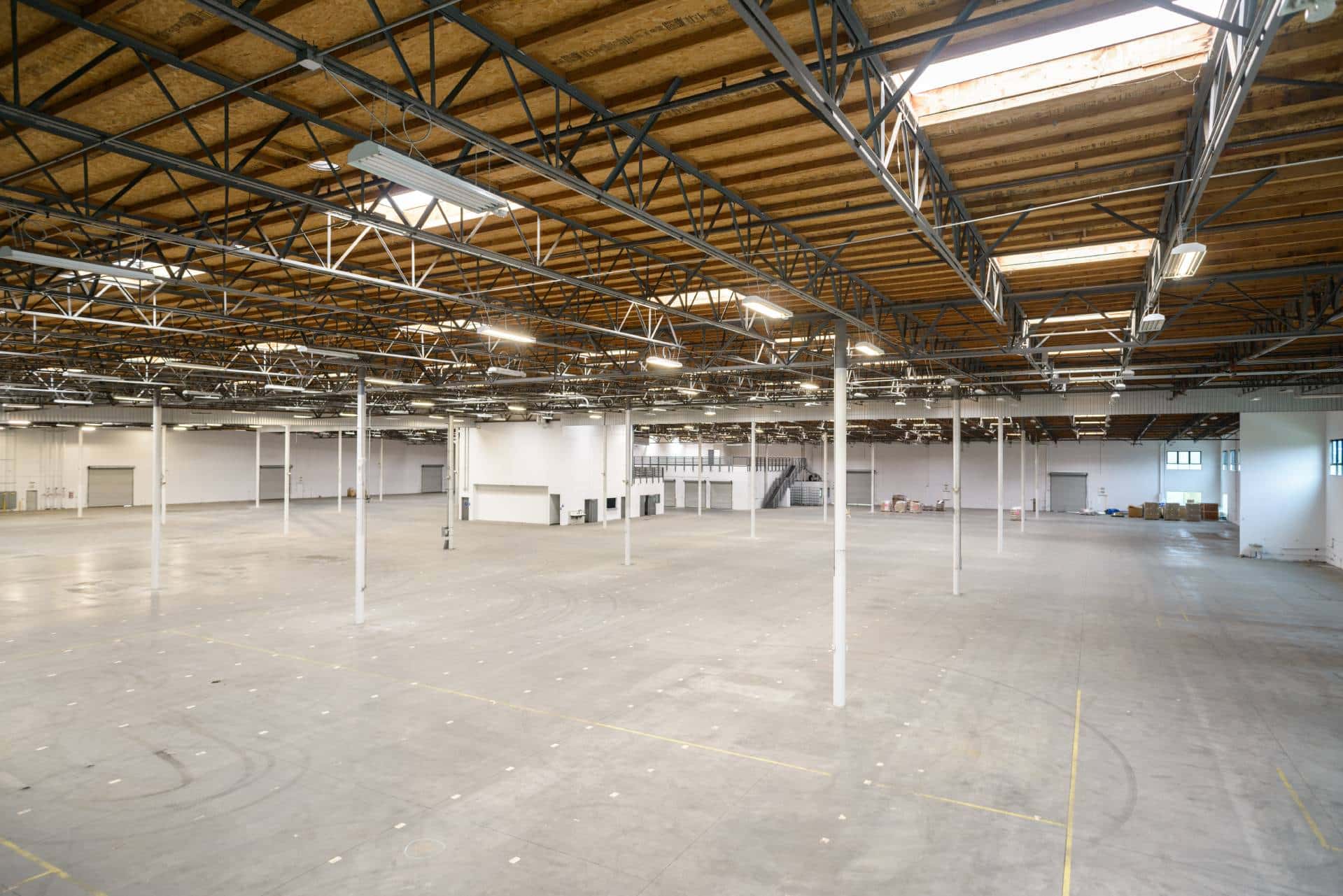

Skyline Construction specializes in planning, developing, and executing a wide range of industrial and manufacturing projects. Whether it's a design-build, speculative warehouse, or build-to-suit project, we deliver flexible, customized solutions that deliver on function, aesthetic, and meet budgetary goals. Our expertise includes advanced manufacturing, complex tenant improvements, concrete tilt-up, and pharmaceutical production facilities with strict requirements.

AN EXPERIENCED PARTNER

INDUSTRIAL AND MANUFACTURING CONSTRUCTION COMPANY

Skyline Construction takes pride in providing an exceptional experience to all of our commercial renovation partners. Cost transparency, clear communication, efficient management, and a people-first approach are the foundation of every Skyline project.

- Precision-Driven Execution

- Precision-Driven Execution

- Seamless Construction

- Future-Ready

- TRUSTED & TRANSPARENT

PRECISION DRIVEN EXECUTION

Our teams understand the complexity of industrial environments. We bring meticulous planning, technical coordination, and boots-on-the-ground problem-solving to every project.

SEAMLESS CONSTRUCTION IN LIVE ENVIORNMENTS

We’re experts in building around your operations—safely, efficiently, and with minimal disruption. Our flexible approach ensures your facility stays productive while we build.

Future-Ready Flexibility

We deliver thoughtful build outs that are designed and constructed to adapt — from robust infrastructure to high-performance finishes that stand up to 24/7 operations, automation, and evolving logistics.

Transparent Process, Trusted Partnership

Skyline is 100% employee-owned and deeply committed to transparency and accountability. You’ll always know where your project stands, with zero surprises and a team that’s in it with you from day one.

EXPERIENCE THROUGH THE NUMBERS

INDUSTRIAL AND MANUFACTURING BUILDERS

59

Projects Built

$2.7B

Total Project Value

8M+

Square Feet Built

INDUSTRIAL & MANUFACTURING

EXPERIENCE THE BUILD

RECENT PROJECTS

INDUSTRIAL AND MANUFACTURING

CASE STUDIES

FAQS

Industrial construction often involves complex infrastructure, active production environments, and strict safety and regulatory requirements. Projects must be carefully planned to avoid disrupting operations while meeting technical and environmental standards.

Industrial facilities are designed for functionality and performance, often requiring heavy-duty structural systems, specialized equipment installations, and support for mechanical, electrical, and process systems that aren’t common in commercial spaces.

Working around active machinery, hazardous materials, or confined spaces requires enhanced safety measures. Industrial projects demand rigorous safety planning, compliance with OSHA regulations, and often, alignment with site-specific protocols.

Many industrial facilities operate 24/7, so construction must be phased carefully to avoid impacting production. Delays or disruptions can lead to costly downtime, making tight coordination with plant operations essential.

Industrial builds often include systems such as process piping, heavy mechanical and HVAC systems, clean environments, and reinforced slabs or pits for equipment installation. These require close coordination between engineering, procurement, and construction teams.