Project Details

FROM BLANK SLATE TO BREAKTHROUGH

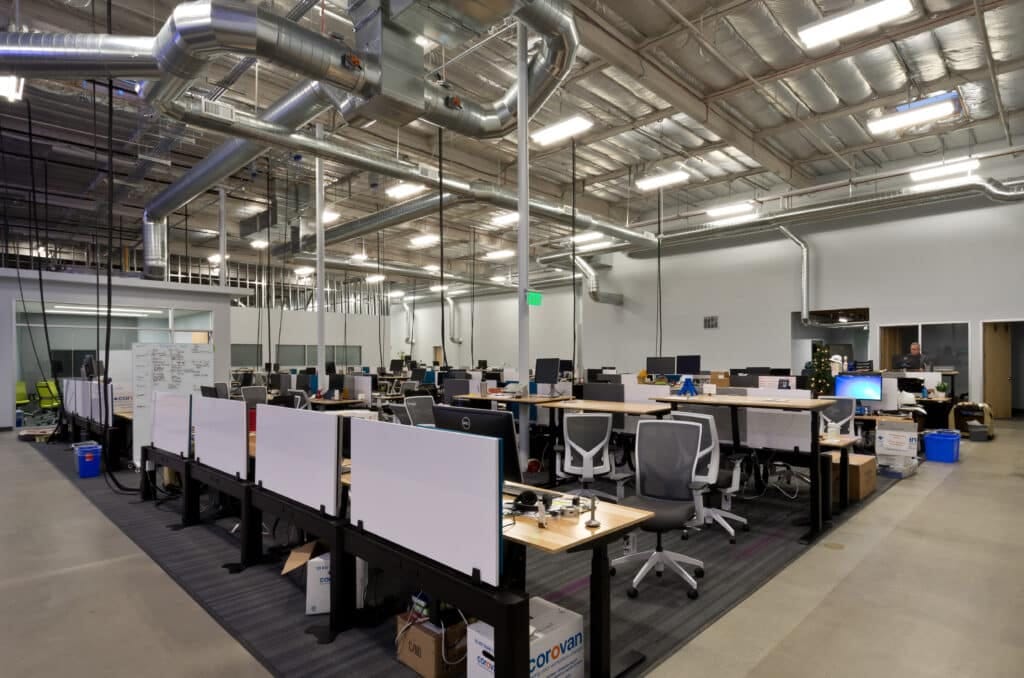

The renovation began with a complete interior demolition of the existing warehouse. Skyline joined the team shortly after design development and provided extensive value engineering to optimize scope, performance, and cost. Structural upgrades included roof enhancements and foundational improvements, along with a full replacement of mechanical, electrical, and plumbing systems. The new layout features a 20,000 sq. ft. manufacturing area designed for assembling, testing, and calibrating Carbon’s proprietary 3D printers. The space also includes dedicated prototyping labs and collaborative work zones that support continuous innovation and product refinement.

Project Details

BUILT TO PERFORM AT SCALE

To meet the technical demands of Carbon’s operations, the building was equipped with upgraded HVAC systems to regulate environmental conditions essential to 3D printing precision. The electrical infrastructure was completely reworked to provide consistent, high-capacity power to the production floor and lab environments. These improvements enable Carbon’s teams to operate at scale, from early-stage prototyping to full equipment deployment.

Spotlight

FEATURES

Every project is fully customized to satisfy the specific needs of our client’s business. Here are a few features that make this space especially unique.

MANUFACTURING SPACE

20,000 sq. ft. built for 3D printer assembly, testing, and calibration

PROTOTYPING LABS

Designed to support advanced additive manufacturing workflows

HVAC UPGRADES

Installed to maintain optimal environmental conditions for production

STRUCTURAL UPGRADES

Included roof improvements and foundational reinforcement

FULL MEP REPLACEMENT

New electrical, plumbing, and mechanical systems throughout